tearing test of fabric|tearing strength of fabric : export The Elmendorf tear tester helps manufacturers assess the tear resistance of fabrics used in clothing, such as denim, woven fabrics, and knitted materials. By ensuring optimal tear strength, garment manufacturers can . webThe Sangha Som Pou is an active community of mindfulness practitioners, inspired by the teachings of Zen Master and peace activist Thich Nhat Hanh. This sangha is a local .

{plog:ftitle_list}

WEBCatarina Paulino 😏🔥 BR_92. 3212,3K. Catarina Paulino Roludo66. catarina. Catarina Paulino photos & videos. EroMe is the best place to share your erotic pics and porn .

Tearing strength is the resistance of the fabric against tearing or force required to propagate the tear once it is initiated. Generally, the resistance offered by a textile material when it is subjected to sudden force is generally termed as tearing strength.Textile Learner is a reference guide for textile engineering. It helps to update . The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in . The Elmendorf tear tester helps manufacturers assess the tear resistance of fabrics used in clothing, such as denim, woven fabrics, and knitted materials. By ensuring optimal tear strength, garment manufacturers can .

1.1 This test method covers the determination of the force required to propagate a single-rip tear starting from a cut in a fabric and using a falling-pendulum (Elmendorf-Type) .Tensile testing tests a fabric’s strength and elongation properties, with two common methods the grab test ASTM D5034 and the strip test ASTM D5035. Tear testing measures the resistance of fabric to tearing using three popular .

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under .Originally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric.

ODM Box Compression Tester

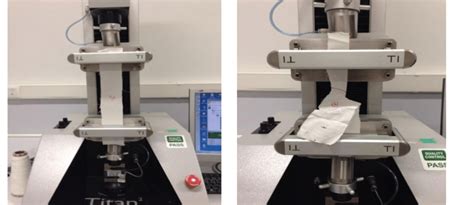

ASTM D5587 is a testing specification that determines the tearing strength of textile fabrics by the trapezoid procedure using a recording constant-rate-of-extension-type (CRE) tensile testing machine.

The force needed to tear a fabric is known as its tear strength, an important aspect that determines a fabric’s capacity to withstand damage with time. The ASTM has developed a standard test procedure for evaluating . Principle of Elmendorf Tear Test. It is measured by measuring the pendulum at a certain starting height to fall, all the potential energy into kinetic energy and then through the reduction of its potential energy converted into .Originally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric. This test method .

Press Start on the controller and record the tearing force. When the crosshead has moved to produce approximately 6 mm (0.25 in) of fabric tear, record the single-peak force or multiple-peak forces. Stop the test after a total tear of 75 .

Delft Tear Test: Specifically designed for geotextiles, it involves a specific specimen shape and method for evaluating tear resistance. . ASTM D1424-09(2013)e1: Standard Test Method for Tearing Strength of Fabrics by Falling-Pendulum (Elmendorf-Type) Apparatus. Application: Applied to fabrics, utilizing the Elmendorf apparatus to determine .If you were to try and tear the fabric without cutting beforehand it would be very difficult and then you would be carrying out a different type of test which would almost be a tensile test. A tear starts with a snag on clothing etc., then the fabric has a small cut in it, so if the force continues the fabric will then tear. The cut before . Research on the tearing of fabric membranes has a long history, which can be traced back to 1915. 8 At that time, the trapezoidal tearing test and tongue (single tongue and double tongue) tearing tests were widely used in the garment field. In 1945, Krook 9 studied the single-tongue tearing of woven fabrics and proposed the concept of a del-zone for the first time.

The tongue tear test is mainly designed to assess the tearing power of fabric with high elongation residences, along with elastomeric substances and stretch fabric. Unlike the Elmendorf and Grab assessments, which focus on measuring the pressure required to initiate tearing, the tongue tear test evaluates the capacity of a material to resist .A tear test applies a force to a material that already contains a partial fracture or rupture otherwise known as a “tear” in order to bring the material to complete failure. . (tears and holes). The more common materials that benefit from tear testing are textiles, fabrics, elastomers, rubbers, polymers, packaging and paper products. Each . 5.2 The force registered in a tear test is irregular, and as a consequence, empirical methods have had to be developed to obtain usable values related to tear strength. In spite of the empirical nature of the reported values, the values are considered to reflect comparative performance of similar fabrics tested and measured in the same way.

Because of the very short tearing time (about 1 s) the Elmendorf test approaches an impact tear test, also referred to as a ballistic (pendulum test method), the test results representing the energy to tear a fixed length of fabric. Specific tear strength is defined as the sum of warp and weft tear strength divided by the fabric mass per unit area.

Standard test method for tearing strength of fabrics by falling-pendulum (Elmendorf-type) apparatus: 07/01/2013: ASTM D2261-13: Standard test method for tearing strength of fabrics by the tongue (single rip) procedure (constant-rate-of-extension tensile testing machine) 01/01/2013:The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in tension. The tear strength is measured as per the ASTM D412 standard test method, which is also used to measure tensile and elongation. The standard test method measures the resistance to the formation .

This test allows manufacturers to determine the strength of the sample. This test complies with the following standards: ASTM D1004 Standard Test Method for Initial Tear Resistance of Plastic Film and Sheeting, and ASTM D5587 Standard Test Method for Tearing Strength of Fabrics by Trapezoid procedure. A tightly mounted fabric is easier to tear than a slackly mounted fabric because the tear force propagates from yarn to yarn as the linear force in the yarn restricts yarn slide. Staple yarn has a lower tear strength compared to filament yarn. In a trapezoid tear test, an increase in ends and picks increases tear strength.

Zhang et al. conducted uniaxial tearing tests with different initial crack shapes, crack sizes, specimen sizes, and loading rates on PVC-coated fabrics and proposed a theoretical tearing model to predict the tearing . The Elmendorf Tear Strength Tester is an instrument specially used to test the tear strength (strength) of fabrics. It uses the impact pendulum method to measure tear strength, also known as the pendulum or falling .

textile tearing strength test

finite element analysis, tearing del zone, tearing strength, tongue-tearing test, woven fabric. Fabric tearing is the act of breaking apart a fabric by. force, without the aid of a cutting tool . This test method uses a computer-based constant-rate-of-extension-type (CRE) tensile testing machine to test the tearing strength of fabrics using the tongue tear process. An Introduction to ASTM D2261 . A common name for ASTM D2261 is the “Tongue Tear Test.” It also has the name of Trapezoid Tear Test. In this regard, fabric tearing resistance is considered by manufacturers and consumers and enhancing tear resistance through optimization of related parameters is beneficial.,In this study, the tearing resistance of a series of shirting fabrics with various weave patterns and weft densities were investigated by both static and dynamic tear test .10. How can fabric tear test results be more accurate and reliable? The Elmendorf Tear Test serves as a vital tool for assessing a fabric’s resistance to tearing and snags. Understanding the test method, procedure, and interpretation of results empowers professionals in the textile industry to make informed decisions about material selection.

import Box Compression Tester

Tear Testing is one of the most basic tests to determine the physical strength of one fabric compared to another. Here's a simple definition: tear testing is a measurement of force required to continue a tear of a fabric specimen assuming that a tear has already been created. Two commonly used methods include Tongue Tear and Trapezoidal Tear.

The tearing properties of coated fabric membranes at high temperature were researched by tensile test with precracked specimen. Refined finite-element (FE) models with yarns were built and verified according to the experiment. . P., Q. Ma, B. Sun, H. Hu, and B. Gu. 2013. “Finite element modeling of woven fabric tearing damage.” Text. Res . The Wyzenbeek method uses a mechanical device to rub test fabrics against an abrading surface in a reciprocal linear motion. The abradant is typically standard #10 cotton duck canvas material or a wire screen. . Wyzenbeek results determine the number of abrasion cycles and double rubs a fabric withstands before exhibiting wear, tear strength .The first part of the test is the tear strength of the fabric which will help to evaluate the tear resistance when the force is applied. Those who do not have any idea about the tearing force will not worry about it. The tearing force is considered to be that force of the fabric that will help you to determine the specific conditions in which .

tearing strength test material

Five fabric samples are taken in parallel to warp and five samples parallel to weft direction; Then cut the specimen of 2.5 inch in width and removing the threads from both the edges until the width has been reduced to 2 inch.

They demonstrated that the properties of the fabric tearing zone, called Del zone, by analyzing of tongue tear test photographs. . One is in-plane tearing test such as trapezoidal tearing method [3–6], central crack tearing method [2,7–14] and single edge notch tearing method [15–17]. The other is out-of-plane tearing test such as .

Standard Test Method for Tearing Strength of Fabrics by Trapezoid Procedure1 This standard is issued under the fixed designation D 5587; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

tearing strength test for fabric

Resultado da Hot Pink Skirt. $25. / month. When you’re feel flirty and want to start showing some skin All of the Above + Special early game builds! Plus extra opportunities for potential Voice Packs, Cheat Codes, or visible in game credits depending on the project we are working on at the time. Discord .

tearing test of fabric|tearing strength of fabric